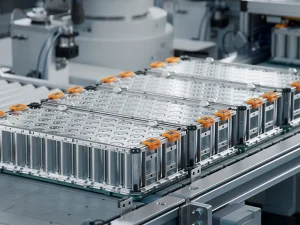

Lithium-ion batteries are now the basis for portable devices and clean energy. Battery production follows multiple sequential procedures. As market demand rises, manufacturers are pushed to develop advanced production techniques. Active research results in improved and more efficient energy storage solutions. But how are they made? The following discussion delves into the manufacturing operations. This guide presents detailed steps of the lithium ion battery manufacturing process. It will detail each process stage’s essential steps, primary methods, and equipment.

What is the lithium-ion battery manufacturing process?

Lithium-ion battery manufacturing is complex and relies on lithium ions for power. It involves several key steps, each crucial for making efficient batteries.

Manufacturers start with raw materials and convert them into working battery components. The basic parts include electrodes, separators, and electrolytes. They are assembled into a complete cell. Precision and quality control are essential, and safety is a top priority.

After Lithium-ion battery assembly, the cells are carefully tested to ensure they meet performance standards. Lithium-ion batteries have many advantages. They store a lot of energy and last longer. They also minimize power loss. The batteries provide numerous practical applications throughout different industrial sectors.

The intense market requirements for these batteries push businesses to build novel solutions. The battery industry is moving forward with continuous technological advancements. Advanced battery technology offers advantages, including longer operational durations, improved security systems, etc.

The 10 Steps in Lithium-Ion Battery Manufacturing

1. Slurry Mixing

Slurry mixing is the first step in lithium-ion battery manufacturing.

The slurry incorporates multiple essential components. It contains lithium metal oxide compounds with binders and conductive additives. The material mixture combines with solvents under vacuum pressure to create a homogeneous liquid suspension. This slurry forms the base for battery electrodes. Binders function to improve adhesion between the active materials. It should have stable properties. This way, it won’t react with electrolytes or during redox reactions.

Proper mixing ensures consistent material distribution and prevents defects. Techniques like hydrodynamic shear mixing or ultrasonic homogenization yield better results. This step takes time and is crucial for achieving high-quality electrodes.

2. Coating

In this step, metal foils coat the slurry. Typically, aluminum for cathodes and copper for anodes. The coating process is crucial. It directly impacts the battery’s operational efficiency and durability. The main objective is to distribute the slurry in a uniform manner. The proper control of roll-to-roll equipment remains essential for protecting foil materials.

There are two types of coating methods. Pre-metered application and roll application. Common coating technologies include slot-die coating and comma bar. These methods allow quick and accurate application. Double-layer slot-die coating is an advanced method. It improves binder dispersion. This boosts battery efficiency and lifespan.

3. Drying

The drying process eliminates moisture and solvents from coated electrodes. Electrode stability and performance depend heavily on this critical step. Infrared technology and ovens help dry coated electrodes in manufacturing. Vacuum chambers speed up the process.

There are several drying zones targeted according to the solvent recovery. This proper drying prevents chemical reactions that can harm the battery’s quality. This process should prevent cracking.

The drying process takes up 48% of the time consumed in the whole Li-ion battery manufacturing.

4. Solvent Recovery

Solvent recovery extracts harmful solvents. There are many solvents, including N-Methylpyrrolidone (NMP) used in slurry preparation. Solvent recovery happens via the exhaust system. Since NMP is flammable, it gets extracted through thermal recycling. This process reduces environmental impact and ensures safe production conditions. Recovered solvents can be reused, making the process more sustainable.

5. Calendering

Calendering compresses the coated electrodes using precision rollers. This reduces tiny gaps in the coating (porosity). This is to achieve the desired thickness and density. Denser coatings improve contact between materials. This step improves ion transport and energy density.

Roller pressure and temperature can be adjusted. More pressure makes electrodes thinner and smoother. Heated rollers soften the binder material (like PVDF). This creates better adhesion between materials.

A two-step method is becoming popular. First pass: medium pressure. Second pass: higher pressure. This reduces coating swelling by 30-50%. It also helps batteries keep their charge longer. Manufacturers carefully balance compaction to maintain ionic conductivity while maximizing active material utilization.

6. Slitting

Slitting cuts the compressed electrodes into specific sizes suitable for battery cells. Different shapes include electrode strips, sheets, and discs. These can be used for wound electrodes, stacked electrodes, and coin cells.

Precision cutting ensures a proper fit within the cell housing. Laser cutting is often preferred for its accuracy and minimal material waste.

7. Vacuum Drying

Vacuum drying removes residual moisture from electrodes under reduced pressure conditions. It is a necessary step in Li-ion battery manufacturing. It lowers the boiling point of liquids in the cell. While ensuring sensitive materials are not damaged.

If this step is not completed and remnant moisture is present, it can cause side reactions. Hydrogen fluoride (HF) is produced when moisture reacts with electrolyte salt (LiPF6). It disturbs the cell’s electrochemical performance, damages AM, and increases safety risks.

It prepares electrodes for assembly under controlled conditions.

8. Cell Assembly

Cell assembly involves several important processes. First, the anode and cathode sheets are wound into jelly-roll shapes or stacked in layers. A separator is placed between them to prevent short circuits. The battery structure receives a protective casing for its enclosure. The shape of the battery casing depends on the selected design. It can be cylindrical, pouch-style, or prismatic formats. After enclosure, the cell undergoes electrolyte filling. This is a critical process that ensures proper battery function.

The cell enters a vacuum chamber before evacuating air and moisture. Electrolyte injection occurs in a controlled manner into the casing tube. The electrode materials soak in the electrolyte solution for a time period. The electrolyte permeates every micropore in the materials.

Several methods exist to stop electrolyte leakage and evaporation. Heat sealing for pouch cells. Crimping or welding for cylindrical and prismatic cells.

9. Forming

Lithium ions start moving between the cathode and the anode. This begins the formation process. This process creates a solid electrolyte interphase (SEI) layer on the anode surface. Ideally, it must be thin, non-reactive and electrochemically stable.

The SEI layer stabilizes the battery. It prevents further reactions between the electrolyte and electrodes during operation.

Manufacturers carefully control the formation process, using specific current rates and voltage limits. These controls help create an ideal SEI layer and maximize battery efficiency.

10. Aging

Aging stabilizes the battery after formation by storing it. Controlled temperatures are maintained for several days or weeks. This process improves SEI structure, ensures electrolyte penetration, and stabilizes voltage levels. Aging enhances battery performance, cycle life, and safety.

These steps help make lithium-ion batteries reliable and efficient. They are ready to power today’s devices and vehicles.

Major challenges in the Li-ion battery manufacturing process

Raw Material Supply Challenges

Battery production requires lithium, cobalt, and nickel. Budget planning becomes difficult due to the unstable prices of these materials. Geopolitical factors create frequent instability in supply chain operations. A few countries maintain control over these resources, thus creating delivery disruptions. To maintain stable, consistent delivery, raw materials are purchased at a higher price. This poses a big risk for manufacturers.

High Production Costs

Manufacturing lithium-ion batteries is expensive. Labor and equipment costs are significant. Energy consumption is high, and research expenses add up. Market demand also impacts pricing. When demand is low, costs per unit increase.

Safety concerns

Batteries can catch fire if not made correctly. This can be dangerous for workers and the surrounding environment. Companies must have strict safety rules. They need good quality control. Worker training is important. Managing and storing materials is key to a safe manufacturing environment.

Environmental Concerns

Manufacturing operations utilize dangerous substances. Organizations are taking sustainable measures to decrease their environmental impact. Manufacturers adopt renewable power sources while simultaneously minimizing their water consumption. More businesses are choosing battery recycling, which helps reduce waste and conserve resources.

Key Takeaway

The production of lithium-ion batteries requires extensive procedures. Every stage needs careful attention. This includes making slurry for electrodes and aging. Understanding is key throughout. This will ensure high-quality production and maintain a safe environment.

Beyond the procedure, the industry deals with major challenges. These include the supply of raw materials, production costs, and maintaining safety standards. As demand for batteries grows globally, new methods are being introduced. These are intended to enhance the product and lessen the environmental impact.